The "safety" gene engraved into the bones, Geely Galaxy L7 safety is more than just batteries

As a new generation of super intelligent electric hybrid SUV under Geely, the Galaxy L7 always puts safety first, especially in terms of battery safety. Geely advocates that "no amount can be done too much for safety". Not long ago, the Aegis battery equipped with the Galaxy L7 not only passed the battery needling test recognized as the most difficult to pass in the industry, but also completed the four vehicle-level battery safety tests of 40km/h forward scraping, 7km/h rear scraping, 20km/h negative impact and vehicle bottom support, once again pulling the battery safety to a higher dimension.

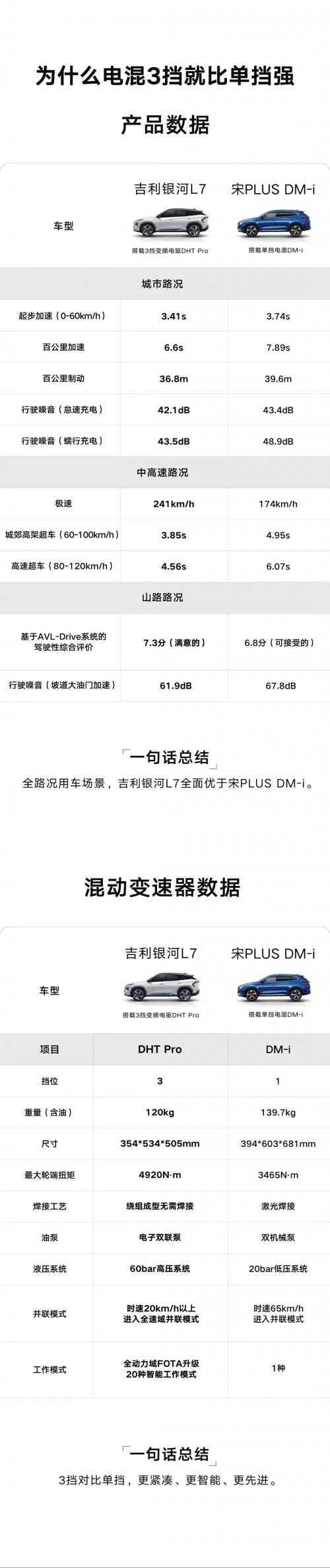

However, the safety of Geely Galaxy L7 does not solely come from battery safety. At the recent Raytheon Electric Hybrid 8848 Full Scene Experience Season event held by Geely, Geely Galaxy L7 is empowered by the technology of 3-speed variable frequency electric drive DHT Pro to show the outside world that under the full scene, the full range of driving safety of Galaxy L7.

Next, let’s take a look at what safety genes the 3-speed variable frequency electric drive DHT Pro has injected into the Galaxy L7.

Generally speaking, traditional extended-range electric vehicles and general single-speed electric hybrid models can cover 85% of travel scenarios, but in the face of high-speed, climbing and other harsh scenarios, the engine must take into account both power generation and drive. In the case of power loss, it is prone to stall accidents. Models equipped with 3-speed variable-frequency electric drive DHT Pro can intelligently adjust the speed ratio according to road conditions and power requirements, and easily cope with all road conditions including highways, ramps, and curves. The power reserve is sufficient, and the output is timely and efficient. With ultra-high power generation efficiency and the advantages of full-speed domain parallel connection and three-speed speed ratio adjustment, it can ensure that the whole vehicle will not stall, and the power will be available at any time.

In the face of demanding working conditions such as climbing and off-road escape, the 3-speed variable frequency electric drive DHT Pro will instantly adjust the energy distribution, gear position and working mode. Through frequency conversion adjustment, it makes full use of the system’s comprehensive power of up to 287kW and the wheel end torque of 4920Nm, and explodes a powerful power reserve in the way of "downshifting and increasing torsion".

In the mountain road, in the face of constant entering and exiting bends, the speed needs to change with the road conditions. But no matter what the situation, the 3-speed variable frequency electric drive DHT Pro not only ensures timely power response and smooth gear shift, but also allows the whole vehicle to obtain stronger tracking and stability, making mountain road driving more secure.

New energy electrification is developing rapidly, and the single-speed DHT "usable and sufficient" state in the electric hybrid market can no longer fully meet user requests. If the single-speed electric hybrid can meet 85-90% of the vehicle scene needs, the 3-speed variable frequency electric drive DHT Pro can meet 99% of the full scene needs with more efficient, more performance and safer overall performance, or will become a high-quality choice for future electric hybrid models.