Do you really know about boron steel?

When it comes to boron steel, in fact, many people have little understanding, and some people even confuse high-strength steel with boron steel. Some people say that the proportion of boron steel is particularly high, so it is particularly safe, but this is only half true. In layman’s terms, the use of boron steel is a matter of conscience; the use of boron steel is good, and the use of boron steel is ability.

Yesterday, I was chatting with a friend who is in the same industry. He has been driving the luxury Sedan for more than 3 years and told me that he wants to change the car because his wife has just become pregnant and the smell in the car has not dissipated. I am afraid that it will affect the child and need to replace it.

I: "Do you like it?"

Friend: "I want to see the new intermediate"

Me: "Oh, just because it’s more environmentally friendly?"

Friend: "Hey, not all of them. Everyone says it’s safer. I value this more when I have children."

Me: "Tell me where is safer"

Friend: "I knew the first person to invent the seat belt…"

You see, in fact, sometimes industry insiders don’t have much better opinions on a certain issue than ordinary consumers. For example, my friend didn’t know that the invention was actually "."

The most shining labels on the body are undoubtedly "safe" and "environmental protection". Perhaps because such labels are too eye-catching, many people do not realize where the safety lies under such labels. Its safety core may be as simple as its Nordic appearance.

Externally Soft and Inner "Steel": The Profundity of Boron Steel in Body Structure

When it comes to safety, it must be mentioned; when it comes to materials, some people say materials; when it comes to materials, high-strength steel must be the word with the highest appearance rate. Today we will talk about the story behind high-strength steel. Boron steel, one of the best structural steels, is the guest here today.

"Hello everyone, my name is Boron, and my English name is Boron. 0.001% of the earth’s crust is composed of my brothers and sisters."

Boron is a non-metal, its hardness in nature is second only to stone, it is widely used in the production of nuclear reactor control rods, and can also be used in the manufacture of alloys. Boron steel, as the name suggests, is a steel that is mainly alloyed with boron. After adding alloy boron, the steel has very high hardenability, high wear resistance and good fatigue resistance, and is an excellent structural steel.

Like many scientific technologies, boron steel was first used in the military industry, especially in the aerospace industry and submarine manufacturing. With the vigorous development of the manufacturing industry, boron steel has a new "application". As a large-scale industrial product, in addition to high strength, good craftsmanship is also an important factor, that is, the difficulty of steel processing cannot be too high. The appearance of boron steel and heat treatment technology perfectly meets this demand.

You might ask, "How?"

First of all, the strength is very high, and the nominal strength of boron steel after hot forming treatment reaches 1500 MPa, which has good safety performance.

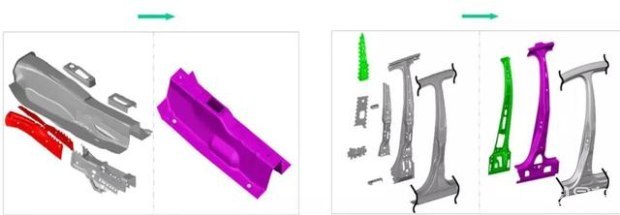

? Secondly, the forming performance is good. The traditional process of manufacturing complex-shaped parts usually requires multiple ordinary steel parts to be welded, while the thermoforming process often requires only one part to solve this problem. The picture below shows the composite diagram of the vehicle B-pillar assembly. The left side is ordinary steel, which requires several parts to be welded. The right side is thermoformed steel, which is integrally stamped and formed, visible to the naked eye.

Combined with these characteristics of boron steel, it is mainly used as structural steel in the industry. The structural strength of boron steel is greatly increased, which improves the anti-extrusion ability, and then protects the life safety of the occupants in the car in the event of a collision. At the same time, boron steel thermoformed parts are also the most valuable lightweight materials at present. Advances in materials and processes make it convenient for people to travel while meeting increasingly stringent safety and emission regulations.

Known for its safety, it naturally excels in the application of boron steel. Its XC90 uses nearly 40% of boron steel, S90 uses 35% of boron steel, and V90 CC and XC60 use 35% and 34% of boron steel, respectively.

Have you learned this knowledge of boron steel?

Of course, you might say that boron steel is so powerful that the more it is used in the car, the safer it is? Let’s continue to look at it.

"Steel" is soft and easy: tell you

How should excellent design be done?

As an important part of the vehicle, it is necessary not only to meet the aesthetic requirements of appearance and vision, but also to meet the requirements of aerodynamics, man-machine performance, and NVH performance. More importantly, it is necessary to protect drivers and passengers against impact.

Generally speaking, people tend to divide the simple into and, which is often not enough when talking about safety. Stephan Ryrberg, senior principal engineer at the Group Security Center, said that a complete collision should be divided into three stages:

The first stage is the energy-absorbing collision of the front structure. This stage generates a specific energy, and we () want the front of the car to absorb as much energy as possible. So sometimes the front of the car looks badly damaged after the collision, but it actually protects us effectively. Of course, the structure must be energy-absorbing and deformed under strict control.

The second stage is the collision of the occupant compartment, that is, the direct collision between the occupant and the restraint system in the vehicle. Seat belts, etc. protect the occupant by absorbing the impact energy to significantly reduce the energy transmitted to the next stage.

The third stage occurs inside the human body, and different organs will collide with each other in the body. If the structure of the vehicle is well designed, the energy transmitted to the second and third collisions will be weakened accordingly, thus reducing the damage to the human body. "

With these insights in mind, let’s talk about what requirements a person who excels in safety should meet.

01

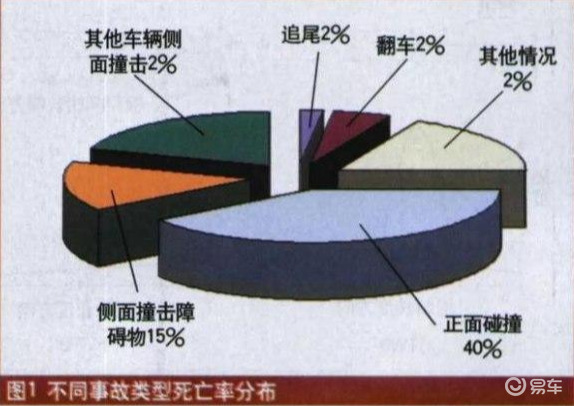

In the investigation of safety accidents, it is shown that the proportion of occupant deaths caused by frontal collisions is the highest, so in the event of a frontal collision, the energy absorption of the front structure has a significant relationship with the deformation of the cockpit. The greater the deformation of the energy absorption zone in a frontal collision, the more the collision energy is absorbed, and the impact force can be avoided as little as possible to the passenger compartment.

This process belongs to the "energy-absorbing collision of the front structure", and in the design, the front should absorb as much energy as possible to reduce the acceleration of the collision.

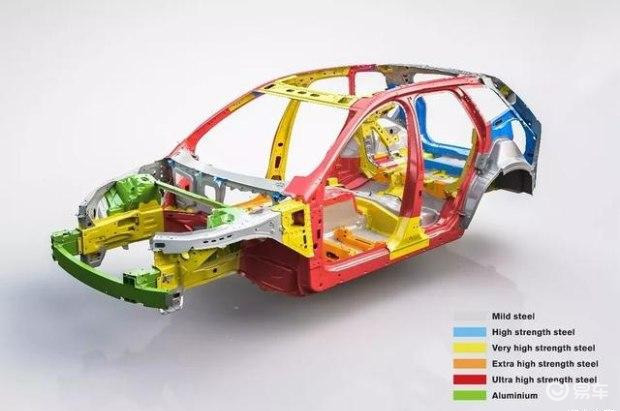

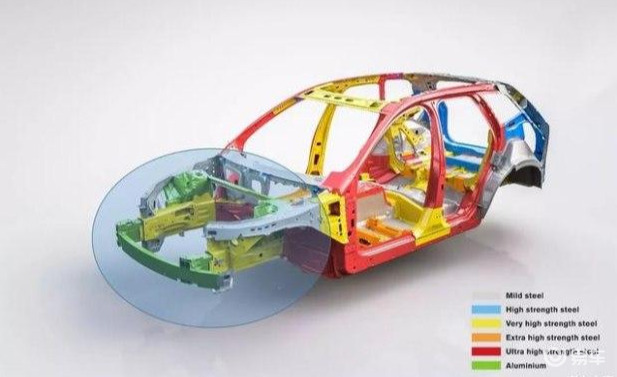

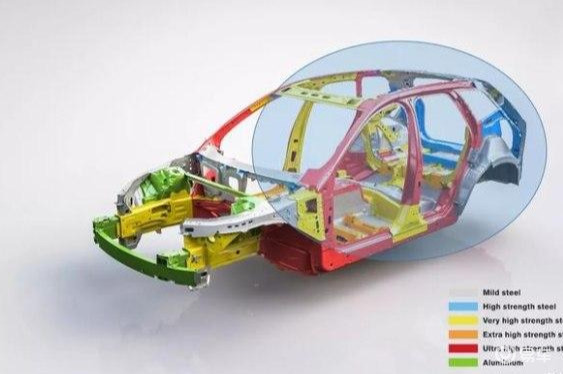

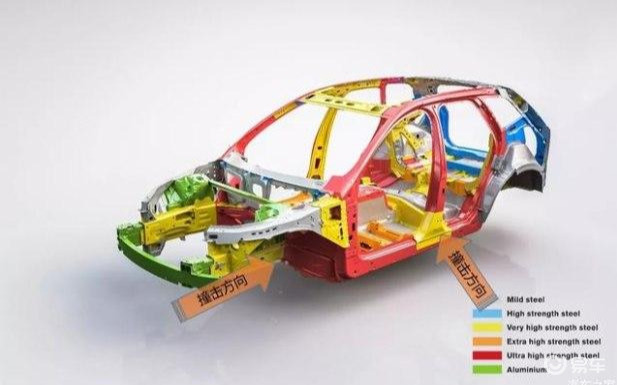

In the frame is the energy absorption design of the front structure. The material distribution map clearly shows the design idea. The yellow front stringer and the green front do not use ultra-high-strength thermoformed steel. The stringer uses medium-strength steel, and the front uses an aluminum alloy cavity structure with lighter weight and better energy absorption effect.

This design can ensure that the front structure can quickly collapse in the event of a frontal collision, which absorbs kinetic energy, thus ensuring the integrity of the cockpit. It can be seen that it is not blindly pursuing strength, but choosing the most suitable material in the appropriate part to ensure the safety of the passengers in the car as the first consideration.

Words like "soft" and "crashless" are often used to describe a car that is not strong, but in fact, through professional crash tests such as E-NCAP, C-NCAP, IIHS, etc., it can be seen that the collapse energy absorption design can greatly improve crash safety, that is to say, a reasonable "soft" is actually conducive to safety.

02

The second most common death rate in a car accident is a side collision. Since there is no buffer zone on the side, there is only one fan away from the outside world when a collision occurs, so the strength and the frame strength of the occupant compartment become the foundation for protecting the occupants in the car. Common measures include increasing the strength of the interior; increasing the strength of the sidewall components, including increasing the cross-sectional shape and thickness of the B-pillar and C-pillar; increasing the strength of the threshold beam; installing a beam system at the height of the B-pillar; and installing reinforced beams below and under the rear windshield.

We still take the XC90 as an example. The part in the blue box above is the most important crew compartment. Its importance can also be seen from the distribution ratio of ultra-high-strength thermoformed boron steel. The red thermoformed boron steel is almost all distributed in this area.

As the saying goes, "good steel is used on the blade", hot-formed boron steel is uncompromising "good steel", of course, it must also be used on the "blade".

The thermoformed boron steel with the best yield strength is used in the side-B-pillar-C-pillar-middle channel-lower threshold and the foot pedal area in front of the driver and co-pilot, that is to say, when you open it, all the hidden under the door frames are thermoformed steel with a strength of up to 1500Mpa; when you sit in the driver’s seat, the pedal area under your feet, and under your center armrest, all use thermoformed steel with a strength of up to 1500Mpa. The front, rear, and left of the driver are surrounded by thermoformed boron steel, forming a safe cage structure.

The purpose of this approach is to effectively transmit the impact force to the protective beams, columns, floors, roofs, and other components in the event of a collision, so that the impact force is dispersed and absorbed by these components, which greatly improves the anti-collision ability and overall safety. It is not easy to deform in the event of a collision, and better protects the safety of the occupants in the vehicle.

In addition, the linear and coherent force transmission path design can maximize the absorption and dispersion of the impact force throughout, whether it is a frontal collision or a side collision, the impact kinetic energy can be evenly distributed to the skeleton through a coherent force transmission path, reducing the deformation of the internal space as much as possible at the moment of impact.