How does basalt weave into a five-star red flag? Can you still be a "fire magic suit"? Exclusive revelation →

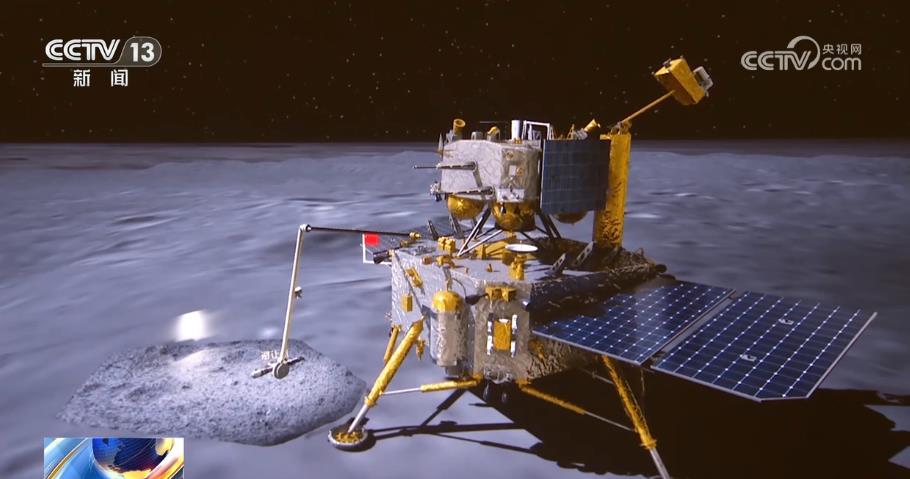

On May 3 this year, Chang ‘e VI was launched from Wenchang Space Launch Site in China, and was sent into the earth-moon transfer orbit by Long March 5. In 53 days, Chang ‘e-6 successfully landed in the pre-selected landing area of aitken Basin in the South Pole of Moon Back, and achieved the world’s first sampling and take-off of Moon Back, and successfully returned to Earth with lunar soil on June 25th, with a round trip of more than 760,000 kilometers.

Behind this success, there are many unknown stories. A series of reports on the science and technology "Chang ‘e" on the Moon explores the scientific and technological forces behind Chang ‘e’s lunar exploration. Today we pay attention to the five-star red flag displayed on the back of the moon for the first time.

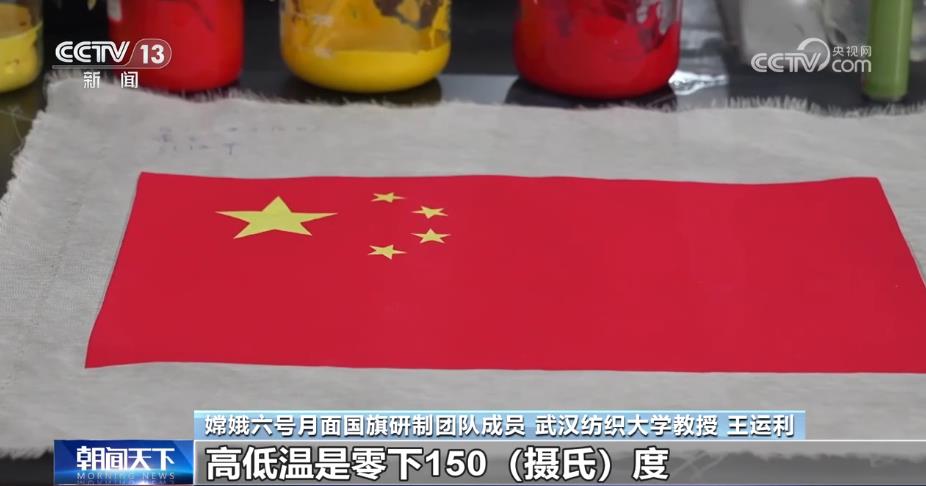

"Stone Edition" Five-Star Red Flag is made of basalt.

The national flag displayed on the back of the moon on Chang ‘e VI has very special requirements for materials. It is made of "stone".

In a quarry in Yuxian County, Hebei Province, a kind of stone called basalt is being collected here. The basalt here is one of the oldest, largest and most complete basalt groups in China.

Zhu Zhaochun, Head of Xinyuan Basalt Mining in Yuxian County:Basalt hasHigh toughness, corrosion resistance, acid and alkali resistance, high temperature and low temperature resistance.Excellent performance.

Zhu Zhaochun knows a lot about the characteristics of basalt, but what he doesn’t know is that,These characteristics of basalt are the materials suitable for the lunar environment that the Chang ‘e-6 lunar flag development team has been looking for.

Wang Yunli, a professor at wuhan textile University, a member of the Chang ‘e-6 lunar flag development team:In the environment of the moon, its high and low temperatures are as high as MINUS 150℃ and above zero 150℃. Because the moon has no atmospheric protection, ultraviolet rays will directly shine on objects. Therefore, for the national flag, it puts forward more stringent environmental requirements.

In addition to the characteristics that can meet the lunar environment, the research team also found that basalt is similar to the lunar soil in chemical composition.

Cao Genyang, a professor at wuhan textile University, a member of the Chang ‘e-6 lunar flag development team:We found that the composition of basalt on the moon is very complicated through the published literature on lunar soil, with 10 to 20 components, the most important of which is silica. We matched and analyzed the stone and found that its data was very close to the composition of the lunar soil. Finally, we chose the basalt mine in Yuxian County, Hebei Province.

In this way, the basalt in Yuxian County, Hebei Province was selected as the raw material for making the Chang ‘e VI national flag. These stones, which have existed on the earth for hundreds of millions of years, have embarked on the road to the moon.

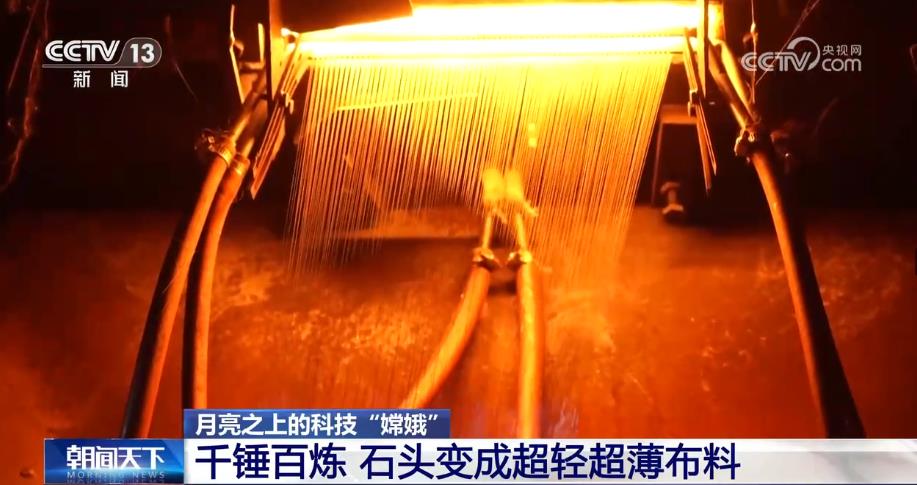

Tempered stones become ultra-light and ultra-thin fabrics.

There is a very important reason why Chang ‘e VI chose the "stone version" national flag to show the back of the moon.Making national flag from basalt is an exploration of in-situ manufacturing of lunar surface..In the future, it is necessary to use local materials to build a lunar base, and to make basalt on the moon into sheet or tubular building materials for lunar surface construction, which will greatly save costs than using materials on the earth.

After the raw materials are determined, how to turn stones into cloth and accurately control the weight?It has become a difficult problem that the development team urgently needs to overcome.

The national flag on the lunar surface of Chang ‘e VI has the same specifications as the national flag on Chang ‘e V, and its size is 300mm×200mm, which is almost the size of a piece of A4 paper. However, the density of basalt fiber is nearly twice that of Chang ‘e V national flag, which will lead to the heavier "stone version" national flag. Because it will be used in spacecraft, the weight requirement of the national flag on the moon surface is extremely demanding, and it needs to keep the same weight under the same size. The developer calculated that this requires the density of basalt fiber to be 8.8 grams per 1000 meters so as not to be overweight, but how can such fine basalt fiber be produced?

Cao Genyang told reporters that the process control, furnace temperature, spinneret state and so on were constantly being debugged, but no matter how to do it, the density index of 10 grams per kilometer became an insurmountable gap in making basalt fibers. After numerous experiments, it is found in a production process that the trapezoidal optimization of the inner cavity structure of the spinneret and the distributed accurate temperature control in the furnace can solve the problem of insufficient characteristics of basalt fibers.

In the end, the development team successfully realized the stable mass production of superfine basalt fiber. The weight of the Chang ‘e VI flag they made was only 11.3 grams, which was 0.5 grams lighter than that of the Chang ‘e V flag.

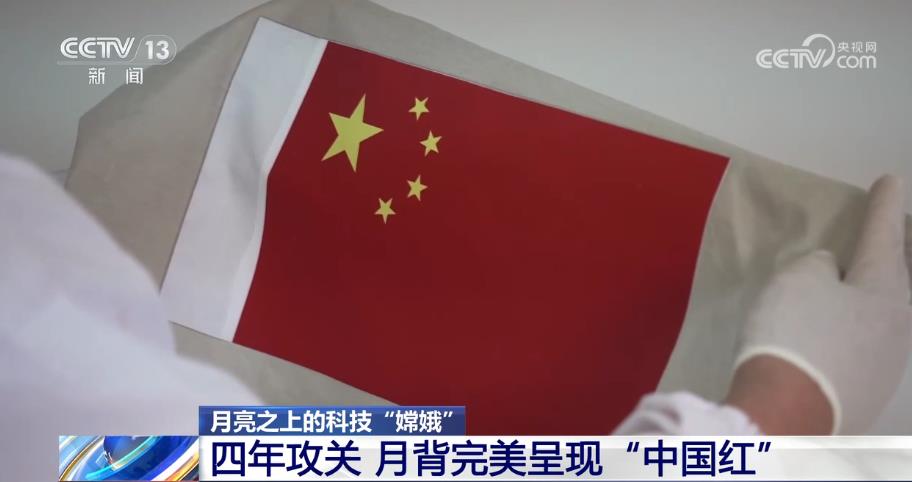

Four years of tackling key problems on the back of the moon perfectly presents "China Red"

Ultra-fine basalt fiber has been made, and the next challenge comes one after another. "How to color the fiber made of stone" has become another difficult problem for the development team.

Different from cloth, the filaments drawn from stone have a particularly smooth surface, and the pigment cannot be firmly attached to the flag surface. The flag is finished, and the color can’t go up. The research team can only try again and again to find a solution.

Finally, based on the experience of Chang ‘e V, the research team used the aramid short fiber hairiness on the surface of the fabric to make the binder in the pigment form a similar "rivet" anchoring effect with it, effectively improving the bonding fastness of the paint interface and the color fullness of the national flag pattern, and ensuring the lunar display effect of the national flag.

Researchers told reporters,From a silk to a flag, there are at least forty or fifty steps in the middle process.Compared with the eight-year research on the development of Chang ‘e-5 national flag, the research time of Chang ‘e-6 national flag is particularly tight, and the team members have almost no rest days, all of which are to ensure that this national flag can withstand the "tempering".

Dr. Sheng Dan, Ph.D., wuhan textile University, member of the Chang ‘e-6 lunar flag development team:There are four mechanical experiments, and there are three steps in environmental experiments, including pre-test and so on, at least 50 steps. Finally, I took a flag and went through a complete experiment from beginning to end, including the final deployment. Later, when I saw the national flag organization unfolding, I felt very cute and proud when I saw the organization unfolding.

The lunar flag development team lasted for nearly 4 years and conquered it.Spinning, Weaving and Color Construction of Basalt MicrofiberAnd many other international problems, the "stone version" of high-quality fabric national flag without temperature control protection and independent dynamic display was developed for the first time, which realized the first independent dynamic display of the national flag on the back of the moon in China. Put the "China logo" on the moon again!

Prospects can be expected. Aerospace science and technology will weave "fire-proof magic clothes"

While the "stone version" of the national flag was being developed,The lunar flag team started the application research of basalt fiber in the fields of heat resistance and flame retardant.. These research results also make basalt more useful.

Natural fibers with golden brown luster are drawn from hard basalt. In the production workshop, a large number of basalt crushed stones are thrown into the blast furnace. At the high temperature of 1500℃, the rocks are melted into liquid, and then drawn into filaments that are almost invisible to the naked eye through the rotating shaft. And this fiber contains a total of 400 monofilaments of 500 microns. Touching a single filament of basalt fiber with your hand makes it feel like a hair filament, silky and extremely tough.Clothes made from them are "magic clothes" with fire-proof function..

The cloth made of basalt fiber combined with textile processing can be used as fire clothes in special scenes, and can also be made into household items such as fire curtains and fire mattresses in the future. At the same time, basalt fiber has broad application prospects in road construction, composite materials, new energy vehicles and other fields.

Wu Minyong, General Manager of Hubei Huierjie New Materials Technology Co., Ltd.:In the field of new energy vehicles, it can be used as a brake pad and a fireproof cloth for battery modules; In the field of aerospace military industry, we use it as an interception network for space launch sites.

(CCTV reporter Cui Xia Li Ning Wu Tianbai Ling Yi Wang Jingya)