Analysis of New Engine Technology —— Art Form of Direct Injection Technology

After the development of carburetor, single-point EFI, multi-point EFI and multi-point sequential EFI, many luxury car manufacturers have made progress in the field of direct injection.

The direct injection engine is different from the ordinary engine in the fuel injection mode. The fuel is injected into the cylinder directly instead of being mixed with air in the intake manifold. With the accurate calculation of the ECU control unit of the engine, this combustion mode can control the fuel injection amount according to the working conditions of the engine, and the performance, fuel consumption and emissions of the engine can be optimized accordingly.

The earliest direct injection system was invented by Bosch Company in 1950s, and was first applied to Mercedes-Benz SL300 in 1955. However, it was gradually forgotten because there was no mainstream development trend at that time. It was not until 1996 that the direct injection gasoline engine reappeared in the market. Mitsubishi Corporation of Japan introduced their GDI direct injection technology into Galant’s 4G93 engine and sold it in the Japanese market. Subsequently, Mitsubishi Carisma equipped with this technology also entered the European market, and today’s "direct injection fever" developed from this.

Facing the problems of energy and environment and the development of engines, Volkswagen, Mercedes-Benz, BMW and Cadillac have invested a lot of manpower and material resources to explore new technical fields. In the domestic market, Volkswagen and Audi’s FSI technology has become a star product in this category, but with the arrival of Cadillac’s new CTS, BMW X6xDrive50i and other models, Volkswagen FSI engines have ushered in more competitors. At present, the mainstream models with direct injection technology in the domestic market are only some high-end models, but we have reason to believe that with the development of technology, this technology beneficial to you, me, energy and the environment will be gradually popularized.

New CTS and its SIDI direct injection engine

Universal SIDI

SIDI all-aluminum dual-mode intelligent direct injection engine adopts universal third-generation direct injection technology. Among them, dual mode refers to homogeneous combustion and stratified combustion. SIDI engine can automatically adopt stratified lean combustion mode when the throttle is half open and automatically enter homogeneous combustion mode when the throttle is full. The automatic conversion of these two modes will directly improve the effective utilization rate of fuel. The method used by general SIDI to realize layering is also different from the eddy current method of Volkswagen, and the controllable oiling process is the key step to realize layering oiling.

Representative model: Cadillac CTS3.6L flagship high-performance version

Cadillac CTS3.6L flagship high-performance version is equipped with this 3.6LSIDI engine. Compared with the previous generation CTS3.6L engine, the maximum power and torque of this SIDI engine have increased by 15% and 8%, reaching 229kW and 374N·m respectively. Due to the introduction of direct injection technology, the fuel consumption of this engine is also reduced by 3% compared with the previous generation engine, and the hydrocarbon emission is also reduced by 25% during cold start.

Volkswagen FSI

Volkswagen FSI has a high reputation in China.

The nozzle of FSI is below the intake pipe, and the nozzle placement of each pair is different.

Volkswagen was one of the first manufacturers to introduce direct injection technology into China. Nowadays, FSI (Fuel Ratio Injection) has become a familiar word for consumers. FSI refers to stratified fuel injection, which is a direct injection technology for gasoline engines. At the beginning of FSI, this technology had stratified lean combustion, but it was later cancelled for various reasons, and only the direct injection technology was retained. Audi used vortex effect to realize stratified lean combustion before. Although this technology was cancelled, the remaining direct injection technology also performed well in terms of power and fuel economy. Compared with the traditional engine that directly injects fuel into the intake manifold, the FSI fuel direct injection engine can significantly improve the power, make the output torque and power higher, and reduce the fuel consumption rate by 15%.

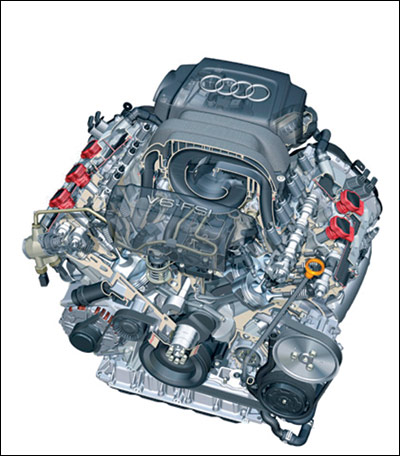

Representative model: Audi A6L3.2FSI

Audi A6L 3.2 has not only quattro four-wheel drive technology, but also FSI.

At present, compared with the previous 3.0LV6 engine, the 3.2LFSIV6 engine equipped on the Audi A6 model has a maximum power of 26kW and a maximum torque of 30N·m and 330N·m, and the fuel efficiency has also been significantly improved. It is a highlight of FSI technology to combine engine power and fuel economy well.

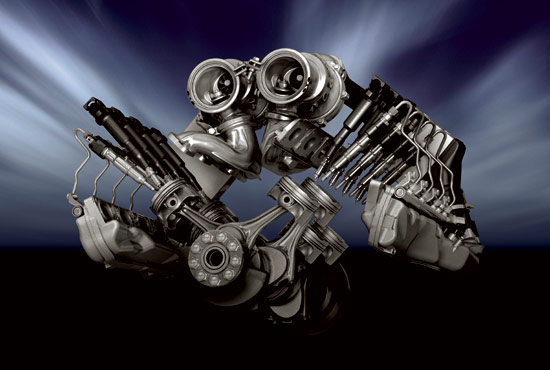

Bmw HPI

From this picture, we can clearly see the direct injection technology structure of BMW.

Many people don’t know about BMW’s high-precision injection system, HighPrecisionInjection. In fact, it is an integral part of BMW’s EfficientDynamics system and an important part of BMW’s improvement in power and fuel economy. The precise piezoelectric nozzle located between the intake valve and the spark plug can provide a pressure of up to 200Bar to fully atomize gasoline and complete the process of injecting it into the combustion chamber in 0.14 milliseconds, so that the fuel economy pursued by engineers is completely guaranteed. BMW does not add stratified combustion technology to this system, but achieves the purpose of improving fuel consumption rate through fuel atomization.

Representative model: BMW X6xDrive50i

BMW X6 xDrive 35i has entered China, and X6 xDrive 50i will meet domestic consumers soon.

The X6xDrive50i, which is about to enter the domestic market, is equipped with this direct injection system, and its power performance is also very remarkable because of its dual turbocharging system. Its maximum power is 300kW, its maximum torque is 600N·m, and its comprehensive fuel consumption is 12.5L/100km (it is worth noting that this is the data of a 4.4LV8 twin-turbo engine).

Mercedes CGI

The highlight of Mercedes-Benz CGI lies in its high-pressure piezoelectric nozzle technology.

Compared with Volkswagen and BMW, Mercedes-Benz’s publicity in this respect is somewhat low-key, but this does not mean that this German company is inferior to its competitors in this respect. Mercedes-Benz has been committed to the research on vehicle power and fuel economy, and CGI (Hierarchical-Charged Line Injection) is their research achievement. In 2006, Mercedes-Benz launched the 350CGI engine, which was the first time to apply the piezoelectric nozzle to the direct injection technology of gasoline engines. Compared with the popular mode of using vortex to produce stratified effect, Mercedes-Benz solves this problem well by using high-pressure piezoelectric nozzle, and forms the required stratified combustion mode by using the spray generated by high pressure. It is also for this reason that this engine effectively reduces fuel consumption by as much as 10% compared with the previous engine.

Representative model: Mercedes-Benz CLS350CGI

At present, it seems that Mercedes-Benz CLS 350 CGI has little fate with domestic consumers.

The maximum power of ordinary Mercedes-Benz CLS350 is only 200kW, the maximum torque is 350N·m, and the fuel consumption per 100 kilometers is 10.1L. Mercedes-Benz CLS350CGI has reached the maximum power of 215kW and the maximum torque of 365N·m, and the fuel consumption per 100 kilometers is 9.1L That is to say, after adding CGI technology, the maximum power, maximum torque and fuel consumption rate of the engine have improved by 7.5%, 4.3% and 10% respectively. Therefore, it can be seen that Mercedes-Benz is not inferior in this respect. After the successful appearance of CLS350CGI in 2006, Mercedes-Benz applied this engine to E-CLASS, S-CLASS and other models, but these models have not yet met with domestic consumers.